Titanium alloys

Ti6Al4V, TI6Al7Nb

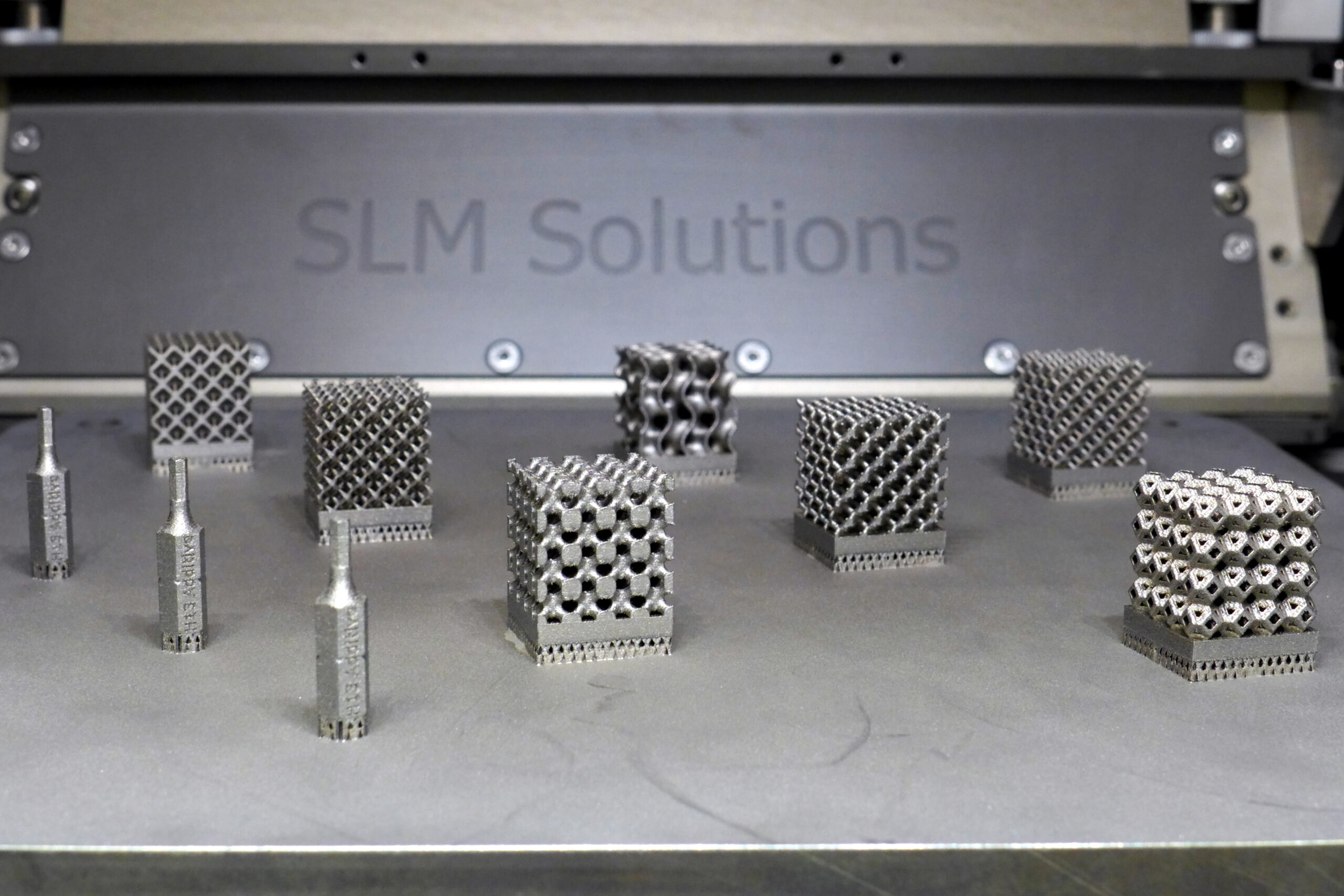

Thanks to the SLM280HL device, it is possible to produce metal parts with minimal porosity. The input raw material is a metal powder with a prescribed grain size. The powder is spread in the building space of each layer of the model and selectively melted using a laser. This binds the current and previous layers and gradually creates the model. SLM technology excels especially in the field of complex parts that are difficult to produce by conventional methods.

Selective Laser Melting (SLM)

280 x 280 x 365 [mm]

20 - 100 μm

113 cm³/h

1.2709

contact us