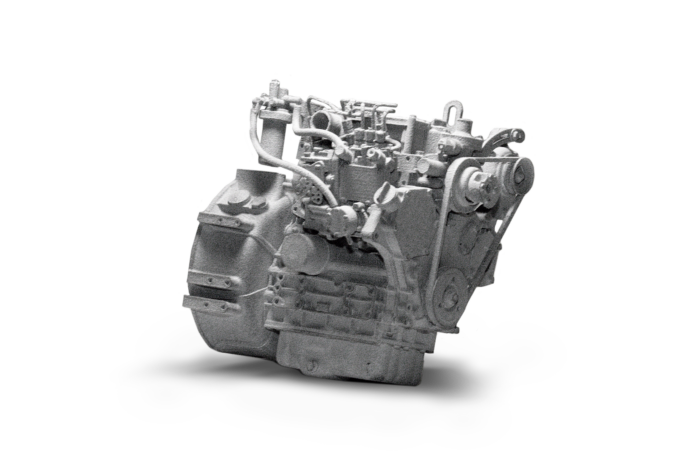

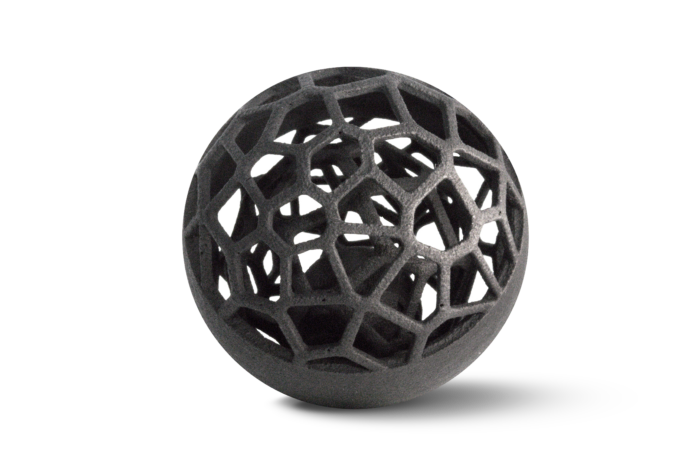

Efficient production of plastic parts

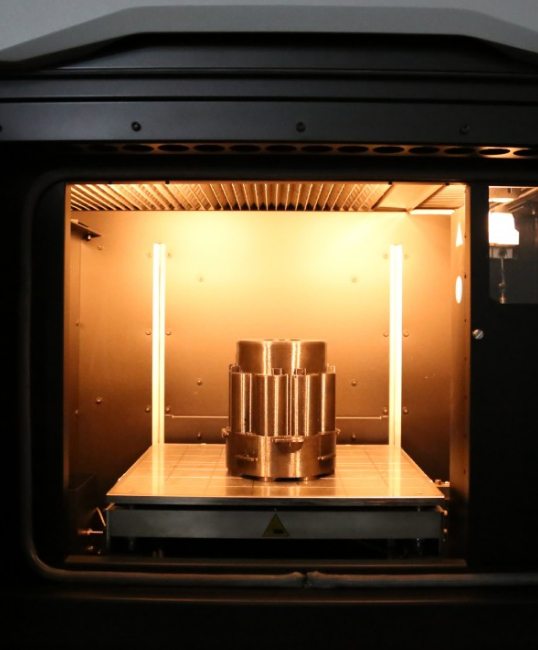

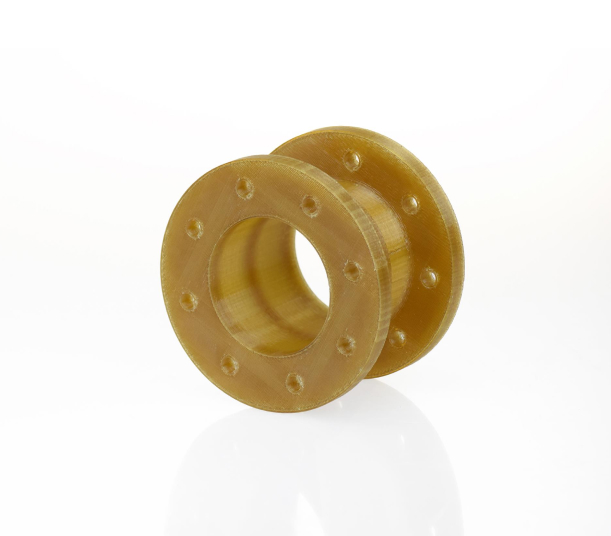

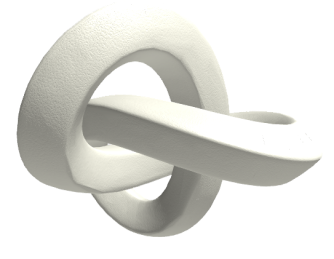

Jet Fusion technology is currently the only 3D printing technology that can cost-effectively compete with traditional mass production of plastic parts. You can prepare a prototype and mass-produce it using a single device. You can produce thousands of parts per week on a single 3D printer and completely in-house. You are not bound by investment in molds. You do not need to deal with bevels or the manufacturability of complex parts.